Gas Burners

The gas boiler burner is the functional part of the boiler that provides heat input by burning fossil fuels, including natural gas, with air or oxygen.

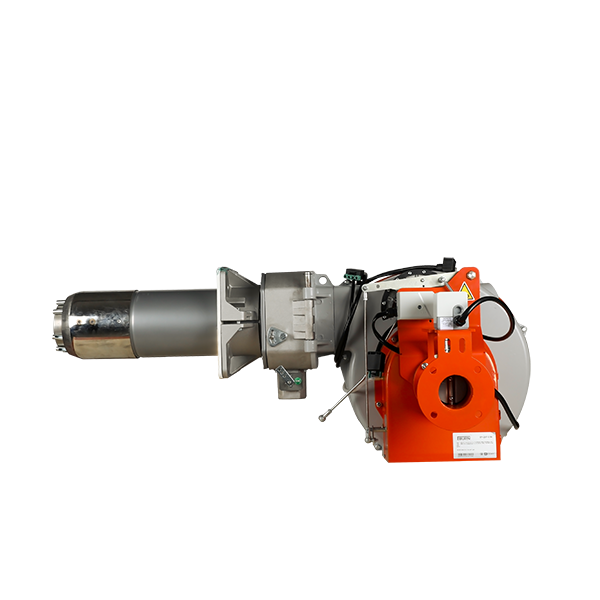

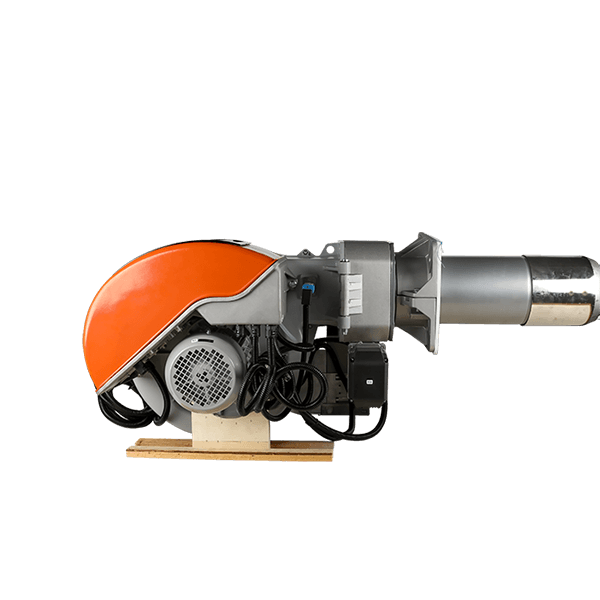

BYQEF0.96FGR Gas Burner Industrial burner Boiler Burner Low Nox

Boiler burner technology uses heat to produce hot water and/or steam. In the combustion process,NOx comes out.

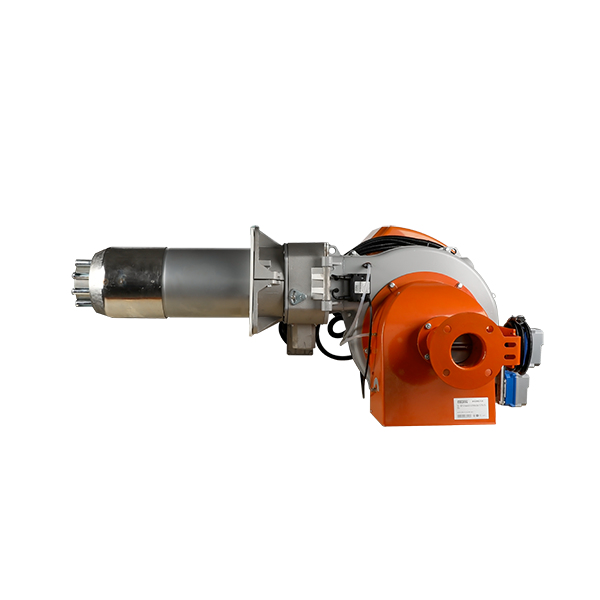

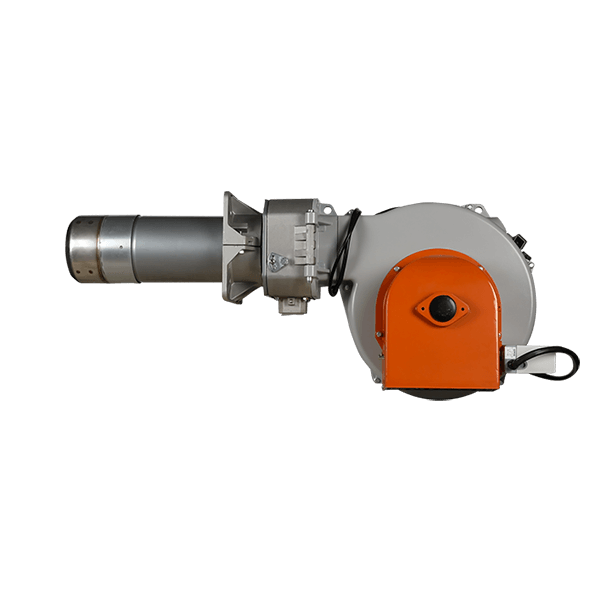

BYQEF4.2FGR hot sale 2022 Gas Burner Industrial Boiler Burner Low Nox burner

In the combustion process, nitrous oxide (NOx) and nitrogen dioxide are produced as byproducts.

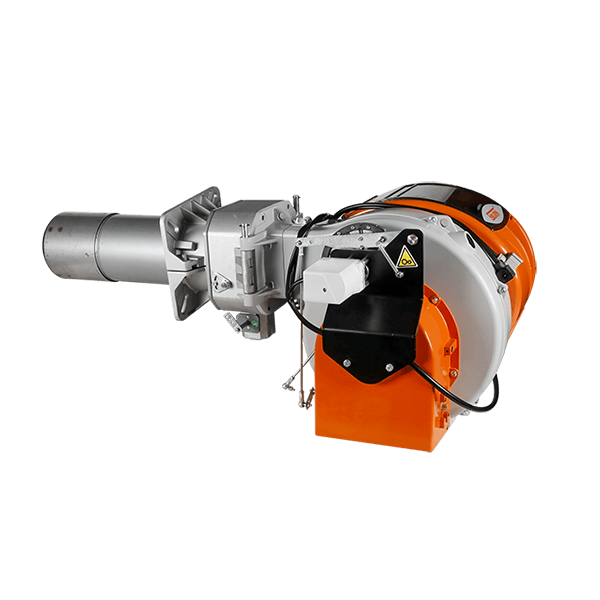

BYQEF0.8FGR Gas Burner Industrial Boiler Burner Low Nox

Boiler burner technology uses heat to produce hot water and/or steam. In the combustion process,NOx comes out.

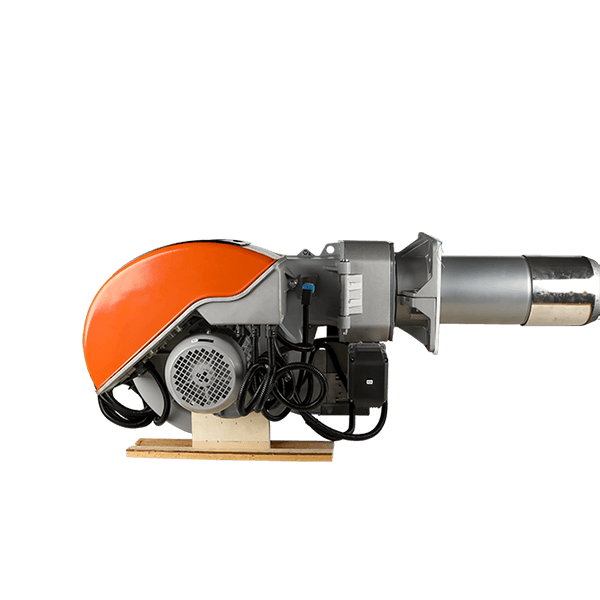

BYG200EFGR Industrial Boiler Burner Low Nox burner Gas Burner

Low NOx burners are designed to control fuel and air mixing at each burner in order to create larger and more branched flames.

BY35P Two Stage LPG Burner for Industrial Boiler Burner

BY35P have been designed and built in compliance with current regulations and directives, applying the known technical rules of safety and envisaging all the potential danger situations.

BY110LXP industrial burner two progressive stage for boiler burner

BY110LXP are used to promote controlled burning. By combining and igniting fuel and air/gas

BY80LXP hot sale two stage LPG burner industrial burner for boiler burner

BY80LXP LPG burner is a mechanical device using an ignition to mix fuel and air together, providing a platform for combustion.

BY120P two stage industrial burner for boiler LPG burner

BY120P burner provides the heat necessary for converting water in the boiler into steam and is attached to the boiler.

BY85P LPG burner two stage industrial burner boiler burner

BY85P LPG burner of two stage is a mechanical device using an ignition to mix fuel and air together to provide a platform for combustion.

The boiler burner is the functional part of the boiler that provides heat input by burning fossil fuels, including natural gas, with air or oxygen. They are available either as part of a manufacturer-supplied boiler kit, as a stand-alone product for custom installations or as a replacement.

Natural gas-fired boiler burners are able to achieve very low emissions. Nitrous oxide (NOx) emission reduction has been a focus for natural gas boiler burners, and some models are able to achieve sub-10 ppm NOx.