Working principle of oil and gas dual fuel burners

Working principle of oil and gas dual fuel burners

According to its working principle, the oil and gas dual-purpose fuel burner can be defined as a kind of equipment that converts substances into heat energy through the chemical reaction of burning—that is, air and fuel are mixed in an appropriate proportion through a premixing device to make it Burn fully. The burner is a thermal energy device that sends fuel and air into the furnace according to the required concentration, speed, turbulence and mixing method, and enables the fuel to ignite and burn stably in the furnace. Fuels are mainly oil and gas. Generally used in small and medium-sized oil or gas boilers.

Principle

When the combustible gas (city gas, natural gas, liquefied petroleum gas) is controlled by the microcomputer control system according to the program and enters the combustion head of the burner, the primary air is mixed with the combustible gas, ignited and combusted, and the secondary air supports combustion to achieve full combustion. The combustion status is detected and controlled by the automatic flame tracking system. When there is a failure in the combustion (oxygen deficiency in the combustion chamber, under-pressure of combustible gas, cut-off of combustible gas, insufficient gas volume, etc.), the control system issues an instruction, and the solenoid valve of the gas supply system is quickly closed. , cut off the gas power supply, the burner will stop automatically after purging, and indicate a fault.

Classification

Gas burners are divided into natural gas burners, city gas burners, etc.

Divided according to the combustion control method of the burner: single-stage fire burner, double-stage fire burner, proportional adjustment burner.

According to the fuel atomization method, it is divided into: mechanical atomization burner, medium atomization burner;

According to the structure, it is divided into: integral burner and split burner. Among them, the split burner is mainly used in industrial production. Its main feature is that the combustion system, air supply system, and control system are all disassembled and installed. This kind of machine is mainly suitable for special working environments such as large equipment or high temperature.

Relatively speaking, commercial burners have a relatively low market price due to mass production and low specialization requirements in the market supply chain, while split burners have relatively high specialization requirements, and Most of them require a professional installation team, and the sales price in the market is relatively much higher than that of the same period last year.

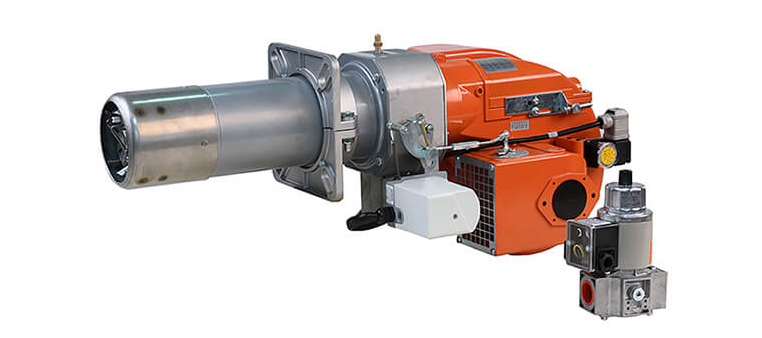

The oil and gas dual-purpose burner adopts the new technology of our company, which integrates the burner, fan, ignition, flame monitoring, air conditioning and other components.

1. Less energy consumption, low noise, high combustion efficiency, and little pollution to the environment

The burner adopts swirling flow and direct current air distribution, and is equipped with a porous mixing device, which ensures sufficient stability of the flame and no risk of backfire, and at the same time makes the mixing of gas and air more reasonable, so the combustion is safe and the smoke is exhausted Clean and less environmental pollution.

2. Safe and reliable, fully automatic control